Kurt Hertzog puts a gloss on things Finishing is an incredibly open-ended topic so even...

Kurt Hertzog puts a gloss on things Finishing is an incredibly open-ended topic so even...

Dave Western explores carving commemorative spoons When I first began carving lovespoons professionally, among...

Howard Butler uses hand cut dovetails for a traditional joint with contemporary appeal My inspiration...

Molly Winton continues her exploration of how to make your mark on turned work The...

Here are seven must-have woodworking measuring tools picked by the editors at the Woodworkers Institute...

Howard Butler uses hand cut dovetails for a traditional joint with contemporary appeal My inspiration...

Dave Western explores carving commemorative spoons When I first began carving lovespoons professionally, among...

Molly Winton continues her exploration of how to make your mark on turned work The...

Richard Findley takes a look at the best way to part off your spindle work...

With the aid of a few machines, Anne Briggs Bohnett and Steve Dando solve a...

You can buy Wooden Jewellery Boxes for only £13.50/ $21.50 (+P&P)! Usual RRP £16.99 / $26.99 🇬🇧...

I often joke that I run on oats. All through the cold months of winter,...

When you are demonstrating you need to show off your talents so David Barron’s toolbox...

Andy Coates looks at a commonly made object and deconstructs it to make something more...

Richard Findley explores a traditional technique When the Editor suggested I should take a look...

The author doesn’t get his fingers burnt with his latest router jointing jig Finger joints...

Guest editor Andy Coates interviews artistic woodturner Tic Challis Tic Challis is an artist and...

Robert Paul Gurney explains how to use ordinary tools to get extraordinarily accurate layouts. The...

Guest editor Kevin Alviti shows how to adorn furniture with hand-carved decorations Carving strapwork is...

Each week we bring you a round-up of interesting and entertaining woodworking content from the...

Colin Sullivan looks at making rope. Both Chatham and Portsmouth dockyards have massive purpose built...

Pat Carroll shows how to make one of his distinctive signature pieces Brick or stone...

Peter Wood uses cleft timber to create a stylised rustic gate For this article I’ve...

Graham Thompson makes the case for unplanned carving ‘Free’ carving, means unplanned, seat- of-the-pants, without...

Duane Cartwright carves a fun, shelf-climbing mouse I have carved this fun little shelf-climbing/sitting mouse...

Alan Holtham creates an elegant project that will make life easier for parents It is...

Geoffrey Laycock looks at essential topics, myths and misunderstandings affecting the safety and health of...

Dave Western researches the history of this traditional Welsh craft The lovespoon has become something...

Each week we bring you a round-up of interesting and entertaining woodworking content from the...

Kurt Hertzog answers readers’ questions I’ve been smitten by pen turning. Easily done, small size...

Danielle Dixon tells WWC how she took up the art of burning wood and shares...

Steve Bisco carves a Norman Romanesque corbel with an 11th-century figure When William the Conqueror,...

Anne Briggs Bohnett emphasises the importance of using truly square stock and offers a few...

In this article we will be looking at the polissoir. These were commonly used tools...

With more than 100,000 species of woods in the world, most turners shouldn’t have a...

After a weekend forging adzes, Nic Westermann sharpens a Crown Gooseneck scraper I have just...

In part one of a two-part series, guest editor Nic Westermann covers the basics of...

Whether you have loose drawers or none fitted at all, here is some useful advice...

Recently I have become less dependent on making measurements and marking cut lines on boards....

Colin Sullivan looks at making rope. Both Chatham and Portsmouth dockyards have massive purpose built...

Philip Greenwood looks at finding the centre of timber. People new to turning, and others...

If you want good strong joints the traditional mortise and tenon is the way to...

In the previous article we looked at how to fix a bowl to a lathe...

This month, Matt Long shows you the cuts you need to make when creating a...

Richard Findley takes a look at the best way to part off your spindle work...

Deciding which joint to use in cabinet and box construction relies on a number of different...

Hand planes are essential tools for woodworking, designed to shape, smooth, and flatten wood surfaces....

How often do you wish there was a better way to do something? We show...

Andrew Thomas looks at using wood finishes Wood finishing is an important and extremely enjoyable...

Bob Chapman experiments with turning pencils to make various forms Making objects from glued-together pencils...

James Duxbury has a gripping idea for easy component sanding. The sanding of small wooden...

Pat Carroll shows how to make one of his distinctive signature pieces Brick or stone...

Molly Winton provides some useful information to consider when burning and branding woodturned projects. This...

We wax lyrical about the sticky subject of keeping your tools shiny and running smoothly....

Brian Kawal introduces a decorative technique that can really make your work standout At its...

Over the years turners usually gather a host of tips and tricks for the ’shop....

Paul Purnell gets crafty with his latest walking stick project Tools Materials Fox head plan...

Charles Mak shares some of his beading techniques while adding an ornamental detail to his...

Peter Benson carves a large sea bird on the wing The wandering albatross and other...

Zoë Gertner gets her daily greens Among the entries in the Veg Growers’ Competition at...

From the height of art deco sophistication and through the mixed up seventies a nicely...

Colwin Way makes another dining table piece. This one’s a real favourite of woodturners and...

Fatigued by metal clamps? Derek Jones builds a set of wooden sash clamps and puts...

Elizabeth Weber carves and paints flowers on Pat Carroll’s lidded vessel Pat was gracious enough...

I never realised that stands for jigsaw puzzles were a thing until I was asked...

Andrew Thomas shows how to carve your own wonderful, decorative seashore shell. Ever since I...

Accurately transferring the location of a hole from one workpiece to another can be a...

The author takes flight with a red grouse in lime The red grouse (Lagopus lagopus)...

An ‘open and shut’ installation job that definitely needed closure. The space in question was...

Mike Darlow turns a chess set based on a trumpet-shape design. The set shown above...

Oz Hassan builds a multifunctional piece of furniture At the end of a tough day,...

Colwin Way makes an out of this world moonlight bowl. So we are in the...

Laurent Peacock outlines the techniques used in the joinery of his Sika console table. When...

You don’t have to suffer from a bad back to realise that our handy kneeler...

Israel Martin describes the process of making a side cabinet with drawers using hands tools...

The author gives you a brief history of letter carving and describes the tools and...

Gary Marshall shows us how to make a traditional temporary woodsman’s working shelter – ‘a...

Sculptor and woodworker Ross Pollard makes an Arts & Crafts-style fumed oak picture frame Arts...

Janice Levi enjoys turning wearable art, so here she turns an artistic and functional piece....

If you need to reach up higher, make this handy hop-up! The fixing method for...

Issue 330 of Furniture & Cabinetmaking is packed with inspiring craftsmanship, from a cherry chest of drawers and a Shaker-style wall shelf to a striking triangular display cabinet rich in symbolism. Discover clever workshop modifications, elegant designs made from offcuts, and expert restorations, plus features on London’s Fallen and Felled initiative and highlights from the Texas Furniture Show. An essential read for passionate furniture makers.

Issue 212 of Woodcarving is packed with inspiring projects and expert guidance, from Steve Bisco’s ancient-style bog oak figure to carvings of wildlife, masks, portraits, and tactile natural forms. Learn how to avoid common mistakes when carving faces, explore the history of netsuke, and discover the intricate work of Jonathan Bayes. With exhibition highlights and community news, it’s a rich and engaging issue for carvers of all levels.

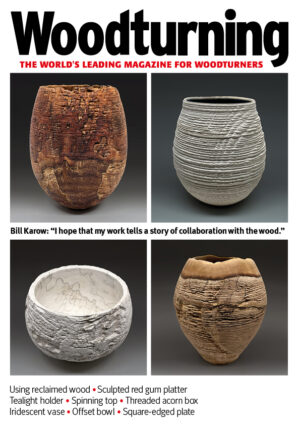

Issue 419 of Woodturning is brimming with creativity, from Mark Palma’s red oak bowls to projects including spinning tops, burr bowls, iridescent vases, and a traditional Scottish quaich. Learn threading techniques for an acorn box, find inspiration in rescued timber transformations, and catch up on competition highlights and community news. A vibrant and varied issue for woodturners of every level.

Issue 98 of Woodworking Crafts is full of practical projects and creative inspiration, from carved book stands and Valentine’s lovespoons to router jigs and wooden fruit. Learn techniques including pyrography, composition ornament making, and Domino Joiner tricks, plus get expert advice on planer-thicknessers and turning tool adapters. With profiles of inspiring makers and Wood Award winners, it’s a rich and rewarding read for every woodworker.

The Art of Chairmaking is a step-by-step guide to building elegant Windsor chairs and other classic furniture. It covers tools, techniques, and five projects—including a stool, table, bench, and two armchairs—with clear photos and diagrams for all skill levels.

Release dates: UK 08/2025 | US 09/2025

Seasoned woodcarver Peter Benson introduces the basics of whittling with safety tips, essential tools, and clear, progressive projects. With step-by-step guidance, readers build skills as they carve a dolphin, polar bear, kingfisher, and more.

Release dates: UK 06/2025 | US 10/2025

This book features detailed projects for crafting decorative boxes—from small ring boxes to multi-drawer designs—using techniques like dovetailing, inlay, and veneering with fine woods like walnut and sycamore. With step-by-step photos and personalization tips, readers can create meaningful keepsakes or gifts. Projects include a ring box, wedding box, jewellery box, and heirloom Bible box.

Release dates: UK: 06/2025 | US 10/2025

Routing is a complete guide to using router trimmers and tables, featuring 16 accessible projects. Compact and affordable, trimmers handle most routing tasks, from cutting to joining. With clear tutorials and tips, projects include a storage box, photo frame, and chopping board—perfect for all skill levels.

Release dates: UK 05/2025 | US 08/2025

Wood Identification & Use is a comprehensive guide to over 200 wood species, with detailed descriptions, colour photos, and information on properties, uses, and safety. Aimed at small-scale woodworkers, it covers everything from cabinetmaking to carving, with sections on defects, figuring, health risks, and inspiring finished pieces.

Release dates: UK 05/2025 | US 09/2025